Saturday, December 23, 2023

Wing rib prep, wings part 8

Saturday, December 16, 2023

Wings part #7

Started the task of prepping all the wing ribs today.

Marked some of the FWD ribs for removing the built in mount flange. Why they put them there just to have you cut them off will remain a mystery.

For the inboard ribs that connect to the front stub spar, they have you remove these front most flanges.

Thursday, December 14, 2023

Wings part #7

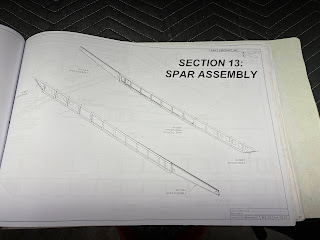

Wing spar assembly....

Riveted the inboard hinge brackets together. The KAI's say to put the rivets in random. I did not and they turned out fine.Aft spar doublers get riveted. Pay attention to which ones to leave out and what type of rivet goes where!

Wednesday, December 13, 2023

Monday, December 11, 2023

Wings part #5!

Prepping the wing structure for priming.

Should be able to get these primed after work tomorrow. It is getting harder to have good weather for priming,

On top of all of this Van's filled chapter 11 and we are trying to determine what our path forward is. More to come here!

Saturday, December 9, 2023

Wings part #4!

Working on all the operations needed for the wing structure parts.

Countersinking all the front spar flange holes.Friday, December 8, 2023

Wings part #3!

Working on the front and rear wing spars and hinges.

Front spars are prepped.

Cleaned up the rear spar doublers.

Wednesday, December 6, 2023

Wings part #2!

After priming all the wing main wing spar parts, I riveted them to the main spars.

Another thousand rivets bites the dust!

Monday, December 4, 2023

Friday, December 1, 2023

Fuselage center section #92 - Fuel Tank part 4!

Today I declared the tank leak free.... Here is how I pressure tested my tank.

The only problem is that it leaks like a screen door around the center bolt. I tried everything to stop the leak. Put grease on the seals and everything else I could think of. Nothing helped!

Then shoved the plug into the port and tightened. This worked perfectly! Stopped the leak path up thru the center of the plug. The balloon conforms to the shape of the inside of the plug and forms an air tight membrane.

I used an old fashioned U tube water manometer and a digital manometer to monitor the pressure in the tank.

After three days of watching the pressure, I declared it leak free. The ambient temp and baro does cause the pressure to rise and fall but on consecutive days I checked it at around the same temp and corrected for the minor changes in baro and the pressure remained constant.

Tuesday, November 21, 2023

Fuselage center section #91 - Fuel Tank part 3!

From 11/16 till 11/21, I worked on finishing and sealing up the fuel tank. I then waited a week to pressure test the tank. Here is a video that I put together detailing the process of assembly and sealing. Later will come the process of pressure testing.

Wednesday, November 15, 2023

Fuselage center section #90 - Fuel Tank part 2!

Continued the prep for the fuel tank assembly.

They have you cleco all the ribs into the top skin. Then cleco the bottom skin onto the assy.Then the fuel inlet is match drilled to the assy. At first I cleco'ed the unit to the skin but it left a huge gap. So I removed the clecos and just held it into place while match drilling up to #30. This virtually eliminated the gap :)

There is one hole that must be drilled and cleco'ed from the inside.

And then you bend the fuel level sender per the directions. The sender I received was not made like the one in the KAI's. Therefore I just made it look as close as possible to the full size template in the directions.

Next I had to countersink the nutplate attach rivet holes in the inspection cover. Make sure the little notch is on the left of the large notch at the bottom.