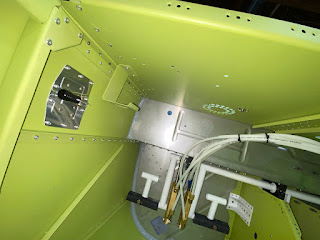

Started by riveting the avionics deck to the firewall. The IS version fills one of the nutplate holes with rivets.

The other two nutplates get installed.

Next you must start assembling the oil tank/battery box brackets.

These are the first two pieces of the bracket assembly that get riveted to the firewall.

Next the side plates.

Then the horizontal ribs.

Had to fabricate this cover that gives you access to the hinge pins.

This clip gets fabricated and riveted to the closeout plate. The hinge pins get captured by this clip.

Next the handle ribs and handle get assembled.

Two nutplates get installed to the handle.

Have to pre-bend the turtle deck skin. Be careful not to kink the skin!

After waxing the area that gets sealant so that it won't stick to the skin, I put down a bead of sealant on the flange and then screwed the skin to the firewall and ribs.

Next I riveted all the nutplates on the upper instrument panel mount flanges.

And then cleco'ed the flanges to the upper skin.